After educating as a mechanical engineer, he got his first full-time job in 1987, and invested almost all the money he had been earning in his first audio system, comprising an NAD amplifier, Dali speakers, and a Micro Seiki DDX 1500. Later on, he also used a Linn Sondek and occasionally also an Axis. "In his apartment, he had a super stereo, but initially almost no furniture," Eva Seiberg states with a twinkle in her eyes about that phase in his life. Johnnie Bergmann, however, quickly redirects our attention to his developments: At that time he already got convinced of the superiority of air bearings for turntables and tonearms, and way back in 1988 he started to draw his first drafts for the bearing of the Sleipner. His reference then had been the Forsell Air Reference.

In parallel to his main occupation in a company for tool manufacturing, Johnnie Bergmann started developing and producing his first turntable during his leisure time. And for a long time to come, as well as later for the first series of ten Sindres, he crafted almost all the necessary parts on purely mechanical milling and lathe machines—by merely using his hands and brains. In the fall of 2008, the small-lot series got completed, and its builder hoped to sell it within a year—but this planning quickly proved wrong. After a Danish web magazine had presented the Sindre, within one or two weeks three turntables got sold, and just a day after the article had been published, a Norwegian distributor, who wanted to add the Sindre to his portfolio, immediately ordered a turntable. (Incidentally, Bergmann Audio is still working with this distribution company up to the present.) Shortly afterwards, the Norwegian distributor, and also one from Hong Kong, contacted the Danish couple. To make it short: The initial phase of Bergmann Audio developed so positively that half a year after the Sindre had been presented to the public, Eva Seiberg and Johnnie Bergmann gave up their previous jobs and took the chance on their move into self-employment, a decision that they haven't repented of.

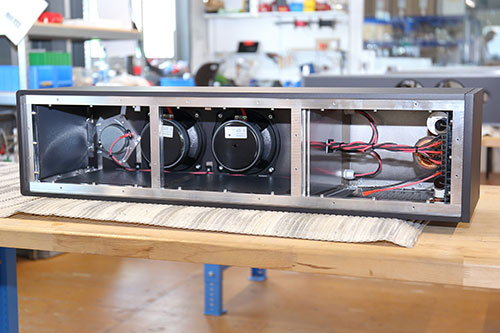

Bergmann Audio quickly extended its portfolio to three models: To the Sindre have since been added the Magne and the Sleipner. And the last happens to be something very special, because here the platter spares a spindle, and therefore avoids any mechanical contact to the non-moving part of the turntable—at least if you decide on the model in which the record is pressed by a weight to the platter, instead of being held in place by a vacuum. In the vacuum version a rubber seal is located between the fixed bearing block with its air outlet apertures and the platter. While all other air-bearing turntables known to me use a spindle that is surrounded by compressed air, thus stabilizing the platter horizontally, the Sleipner features a platter shaped in its cross-section like an inverted "U" and rotating above the bearing block with the air emerging from its top section and laterally all-round. A higher air pressure on the opposite side of the motor ensures that the platter hovers perfectly centered above the bearing block, despite the driving belt exerting its tractive forces on the platter. The air volume therefore has to be adjusted very precisely to allow the bearing to work perfectly and to accentuate the sonic advantages of this principle. As the aforementioned review showed, this turned out to work very well, especially if one relies upon the factory settings. During the testing period, which unfortunately happened to be much too short, there didn't appear any reason at all to change it.

-

Andante-Largo-Chef Suzuki san zu Besuch

Mika Dauphins Drei H Vertrieb hat eine neue Marke in sein Portfolio aufgenommen: Andante Largo mit seinen Racks, Spike-Aufnahmen und einem Kontaktverbesserer. Wie könnte man die Produkte besser kennenlernen als bei einem Besuch von Inhaber Suzuki san und seinem Sales Manager Kai Endo im heimischen Hörraum? An einem Freitagabend schaute Thomas Heckel, der Drei H in Süddeutschland vertritt, in Gröbenzell vorbei und stellte mir die beiden Japaner vor. Das Trio hatte auch jede Menge Taschen…07.03.2025 -

WestminsterLab Omne: Premiere in Hamburg

IAD, der deutsche Vertrieb von WestminsterLab, hatte eine Weltpremiere im Vorfeld der Norddeutschen Hifi-Tage angekündigt: Firmenchef Angus Leung würde aus Hong Kong anreisen und seine neuste Kreation, den Vollverstärker Omne, im Hifi-Studio Wisseling High End vorstellen. Sehen konnte man den Omne, hören leider noch nicht. Nachdem die geladenen Gäste die Möglichkeit erhalten und größtenteils wahrgenommen hatten, die beeindruckenden Räumlichkeiten in der Große Bleichen 34 mit den ebenso beeindruckenden Hifi- und Heimkinoinstallationen zu besichtigen, begann Angus…03.02.2025 -

Ein wenig Raumakustik

Auch wenn man sich über 30 Jahre beruflich mit Hifi beschäftigt, ist man vor Überraschungen nicht gefeit. Tauscht man eine Komponente für einen Test in der stimmig spielenden Kette aus, ist das eben ein Teil des Jobs und man muss auf einiges gefasst sein. Diesmal wollte ich aber nur ein bisschen aufräumen – mit ungeahnten akustischen Folgen. Natürlich habe ich ein wenig zur klanglichen Optimierung meines Hörraums getan: So hängen an den Wänden das ein…30.12.2024 -

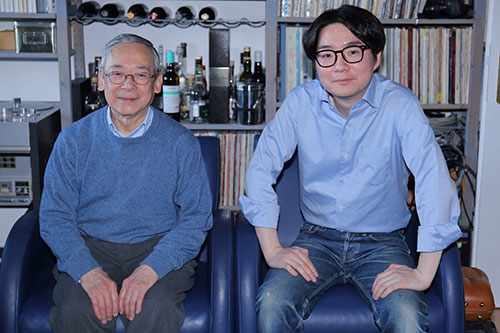

AIM Kabel: Interview mit Akira Oshima und Johnny Lee

Bei der Verteilung von Kabeltests duckt sich Roland Dietl gern mal weg, was bei den AIM Ethernet-Kabeln aber nicht klappte. Dann beeindruckten sie ihn derart, dass er den Artikel über AIMs Top-USB-Kabel selbst initiierte – und sie später erwarb. Auf der Messe in Wien hatte ich die Gelegenheit, mehr über den Japanischen Kabelhersteller zu erfahren. Wenn sich ein nicht gerade als Kabel-affin bekannter schreibender Kollege – und darüberhinaus auch Helmut Baumgartner, der die Strippen nach…20.12.2024 -

High End Wien 26

Im kommenden Jahr wird noch einmal alles so sein, wie es war. Zumindest, was die wichtigste Messe unserer Branche angeht, die High End in München. Das wird dann die 21. Messe dort sein, nach ebenso vielen Veranstaltungen zuvor, einmal in Düsseldorf und danach in Frankfurt. Nach der magischen Zahl 42 geht es dann im Austria Center Vienna weiter. Am besten wäre es, man beginnt in Vorbereitung der High End in Wien schon heute mit leichtem…06.12.2024 -

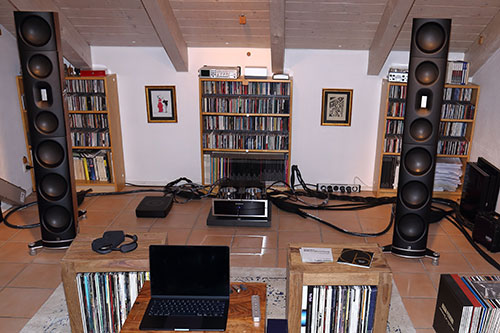

Interview mit Jean-Pascal Panchard – Teil 2

Nach den Ausführungen zu seinem beruflichen Werdegang und einigen Stenheim-Modellen in Teil eins wird Jean-Pascal Panchard auch hier noch über das ein oder andere Modell aus dem Portfolio sprechen, bevor er Fragen zur internationalen Aufstellung der Firma, dem Audio-Club und seinen Lieblings-Medien für Tests und den privaten Hörgenuss beantwortet. Als Jean-Pascal Panchard Stenheim erwarb, hatte man lediglich die Alumine Two mit der optional zu ergänzenden Basssektion im Angebot. Um der Marke internationale Beachtung zu verschaffen,…25.11.2024

© 2025 | HIFISTATEMENT | netmagazine | Alle Rechte vorbehalten | Impressum | Datenschutz

|

|