Moreover, the dismantling and new set-up of an audio system, including the precise alignment of the individual levels, takes quite some time. You can't just switch from A to B and back to A again to verify supposed small differences in sound. If, as in my listening room, there is a lack of available space, one is more than willing to forego a test. Especially when the Finite Elemente website describes the Carbon Edition as "Simply The Best In The World" without any hint of understatement and one has experienced that Luis Fernandes is not prone to empty promises: You don't even want to be tempted after taking a look at the prices of the carbon racks. How fortunate that during a technical chat about power supplies for streaming components, the Finite Elemente developer incidentally mentioned that there is a newly designed listening room in the company's premises where the different generations and designs of Pagode racks can be compared without much effort. At the end of the conversation, a visit to the company was a done deal: This way, the capabilities of the carbon racks could be discovered without the danger of triggering an irresistible "have-to-have" impulse, as when trying them out in my own system.

Finite Elemente's production facilities are located on the first floor of a rear building on one of the main roads in Meschede, close to the town centre. A loading ramp and a goods lift facilitate delivery and dispatch. Generous skylights provide plenty of daylight on the first floor. Not far from the entrance, Werner Möhring and Luis Fernandes have a shared office. There is a lot of storage space for the products of the Cera family and also for equipment, cables and cartridges from the portfolio of the G8 & Friends distribution, whose management Werner Möhring also holds. The centrepiece is, no, not the listening room, but a large room with a centrally placed, electrically height-adjustable assembly table, on which the individual parts are assembled into a rack and finally packed. All racks are shipped fully assembled, as otherwise there would be no guarantee that the fine wood or carbon surfaces and polished aluminium pillars would not be damaged during assembly and that the sonic impact on the components would be exactly as the designer intended. Of course, the freight costs are much higher than if the racks were delivered flat-packed. But Luis Fernandes sets the highest standards for the quality of his products. Questions of cost are of secondary importance.

Incidentally, Finite Elemente has still been working with the same carpentry workshop and the same polisher since it was founded in 1997. Initially, the metal pillars were chrome-plated, but this was not visually convincing at critical points. So Luis Fernandes decided to offer only matt anodised and, for an extra charge, high-polished side pillars. Because of the great variety of versions - there exist seven colour variants alone, each with two finish versions of the metal parts - the racks are only built to order. Yvonne Burmann has been responsible for this for 16 years. Depending on the model, she needs between two and five hours for assembly. Cloths, foils and polystyrene sheets are used from time to time to protect the surfaces from scratches. Special, self-made gauges are also used, for example to screw the frames and the side pillars exactly at right angles together or to adjust the distances between the pillars precisely. Gloves are also mandatory for some operations.

-

STATEMENT in High Fidelity | German Edition 2025

Während der High End 2025 in München wurden die STATEMENT in High Fidelity-Auszeichnungen verliehen und zwar wie immer am Morgen des ersten Messetages. Am darauffolgenden Abend waren die Gewinner dann zum Dinner in eine bayrisches Gasthaus eingeladen. Darüber zu berichten obliegt traditionell meinem Kollegen Wojciech Pacuła Zur Erinnerung: Diesmal wurden von hifistatement.net und highfidelity.pl der Audio-Dateitransport Taiko Audio Olympus XDMI + I/O XDMI und die Lautsprecher Stenheim Alumine Five SX ausgezeichnet. Auf den ersten Blick…06.06.2025 -

Statements in High Fidelity | German Edition 2025

The magazine of my colleague Wojciech Pacuła, highfidelity.pl, and hifistatement.net traditionally award a component at the trade fairs in Munich and Warsaw that impressed us in the previous six months. When the High End will take place in Vienna next year, will we still be able to talk about a German Edition? There will probably have to be some changes to the awards next year, but there are also two novelties this year: My colleague…13.05.2025 -

Statements in High Fidelity | German Edition 2025

Das Magazin meines Kollegen Wojciech Pacuła, highfidelity.pl, und hifistatement.net zeichnen zu den Messen in München und in Warschau traditionell jeweils eine Komponente aus, die uns im vorausgegangenen Halbjahr begeisterte. Wenn die High End nächstes Jahr in Wien stattfindet, werden wir dann immer noch von einer German Edition sprechen können? Bei den Awards wird sich im kommenden Jahr wohl einiges ändern müssen, aber auch heuer gibt es zwei Neuerungen: Der Kollege pflegte mit großer Beharrlichkeit CD-Player…13.05.2025 -

Acoustical Systems Analog Workshop

Kürzlich veranstaltete Acoustic Systems in Person von Axinia Schäfer, die für die Leitung der Firma verantwortlich zeichnet, und Dietrich Brakemeier, dem die technische Entwicklung der Analogkomponenten obliegt, in den Firmenräumen in Hofstetten den 1. Audiophilen Analog Workshop. Der dauerte zwei Tage und endete mit einen Klavier-Solo-Konzert. Auch wenn andere Termine die Teilnahme am Sonntag unmöglich machten, konnte ich mir den Besuch der absoluten High-End-Analog-Schmiede natürlich nicht entgehen lassen, zumal in der Einladung von einem „lockeren…02.05.2025 -

Ein Besuch bei Unison Research und Opera

Nachdem Ihnen Carsten Bussler über seine sehr positiven Erfahrungen mit Unison Researchs Simply Italy Black Edition berichtete, kann ich hier noch einiges zu den daran beteiligten Personen und ihrem Anspruch, aber auch zur Geschichte der Firma nachtragen, schließlich wurde sie schon vor 36 Jahren gegründet und zwar von Giovanni Maria Sacchetti. Ganz so lange kenne ich die Marke zwar noch nicht, aber ich bin ihr bei einem Pressetermin in Venedig erstmals begegnet, als die imposanten…28.04.2025 -

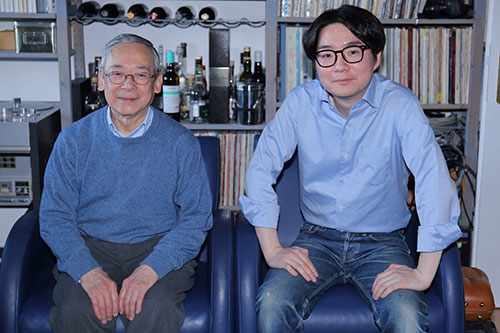

Andante-Largo-Chef Suzuki san zu Besuch

Mika Dauphins Drei H Vertrieb hat eine neue Marke in sein Portfolio aufgenommen: Andante Largo mit seinen Racks, Spike-Aufnahmen und einem Kontaktverbesserer. Wie könnte man die Produkte besser kennenlernen als bei einem Besuch von Inhaber Suzuki san und seinem Sales Manager Kai Endo im heimischen Hörraum? An einem Freitagabend schaute Thomas Heckel, der Drei H in Süddeutschland vertritt, in Gröbenzell vorbei und stellte mir die beiden Japaner vor. Das Trio hatte auch jede Menge Taschen…07.03.2025

© 2025 | HIFISTATEMENT | netmagazine | Alle Rechte vorbehalten | Impressum | Datenschutz

|

|